MANUAL DESIGN OF SINGLY REINFORCED BEAM

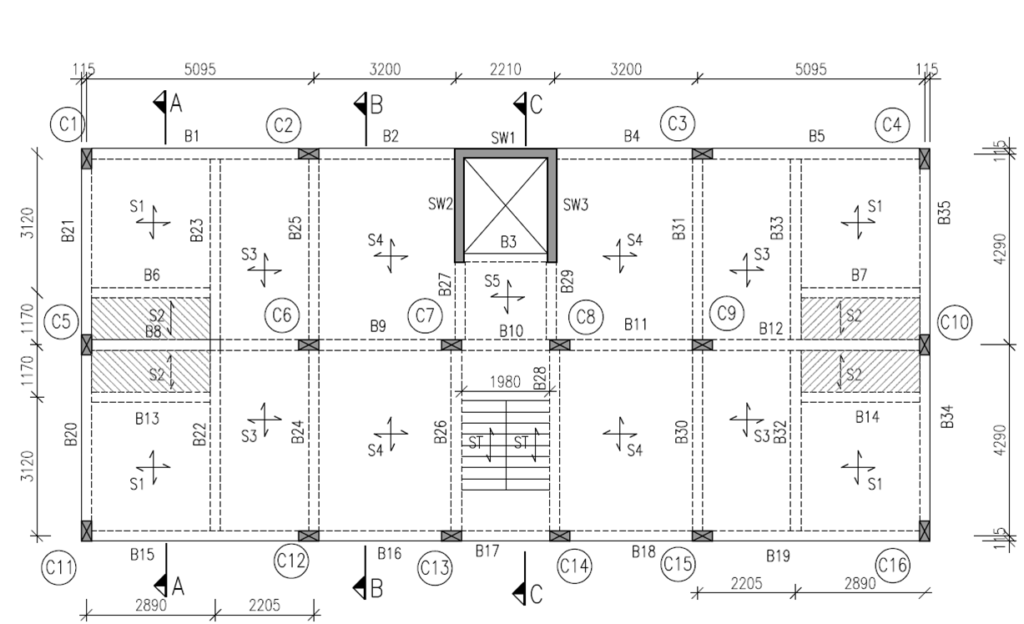

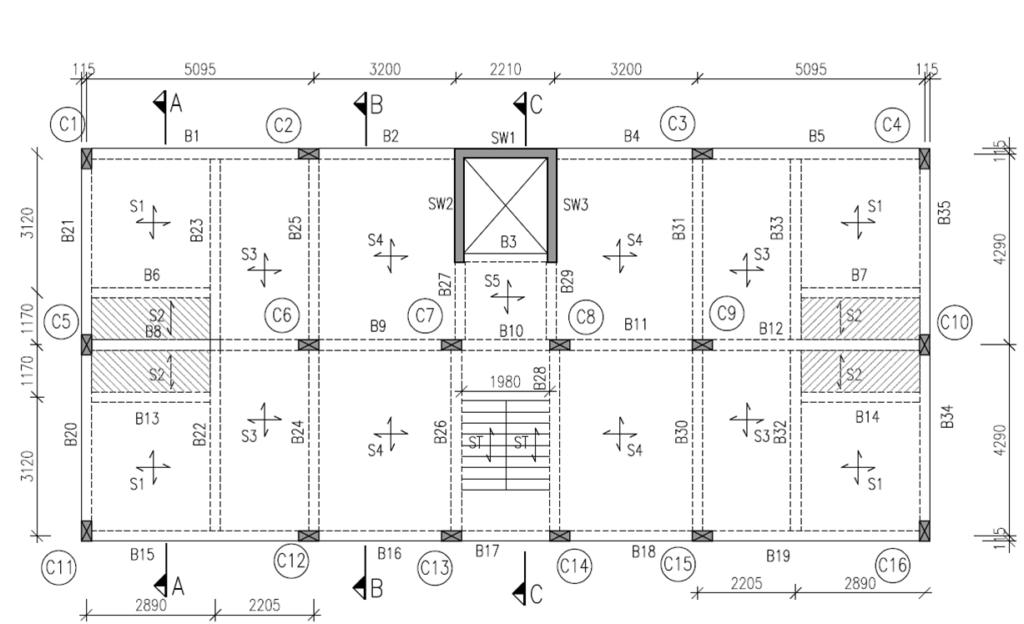

In this blog, you will learn step by step about the design of singly reinforced beam of first floor of G+5 building procedure using I.S. 456:2000. For daily blogs, subscribe to our blog page and learn complete information about the structural engineering industry Given :- (SINGLY REINFORCED BEAM) 1) Grade of Concrete = M202) Grade of Steel = Fe5003) Clear Cover to Reinforcement (c) = 25 mm4) Length of Beam = 2660 mm5) Unit Weight of Concrete = 25 kN/m26) Slab Dimensions :- S1 = (2660 mm X 2890 mm) & S2 = (940 mm X 2660 mm)7) Floor to Floor Height (H) = 3000 mm Step 1 :- Trial Dimension of The Beam :- Assume the Width of The Beam (b) = 230 mmEffective Depth of Beam (d) = (L/10) to (L/15) = (2660/10) to (2660/15) = 266 mm to 177.33 mmTake, d = 300 mm …(Rounded off on Higher Side)Assume, 12 mm Diameter Bars are to be Provided at a Clear Cover of 25 mm.Therefore, D = 300 + (12/2) + 25 = 331 mm ≈ 375 mm …(Rounded off on Higher Side)Therefore, Effective Depth of Beam Provided (d) = 375 – (12/2) – 25 = 344 mm Step 2 :- Effective Span (Le) :- Le = L + d = 2660 + 344 = 3004 mm Step 3 :- Load Calculations :- i) Super Imposed Dead Load (SIDL) :-Wall Load = Wall Thickness X Floor to Floor Height X Unit Weight of Bricks = (0.150 X 3 X 20) = 9 kN/m …(No Deduction of Depth of Beam is Made From Floor to Floor Height)ii) Slab Load Transferring on Beam :-Slab S2 :-a) Self Weight of Slab (DL) = D X Unit Weight of Concrete = 0.125 X 25 = 3.125 kN/m2b) Live Load (LL) = 2 kN/m2 …[Refer Table No. 1 , Page No. 7 , I.S. 875 (Part 2) : 1987]c) Super Imposed Dead Load (SIDL) =Floor Finish = Wt. of Screeding (50 mm Thk.) + Flooring (10 mm Thk.) + Sunk Load(325mm Thk.) = (0.05 X 24) + (0.01 X 22) + (0.325 X 20)…[Refer I.S. 875 (Part 1) :1987] = 7.92 kN/m2 ≈ 8 kN/m2Total Load of Slab S2 (w) = 3.125 + 2 + 8 = 13.125 kN/m2 Rectangular Load of Slab S2 is Transferring on Beam B6 Because S2 Slab is One Way Slab Which is Given by,WS2 = [(w. Lx) / 2] = [(13.125 X 1.17) / 2] = 7.678 kN/mSlab S1 :-a) Self Weight of Slab (DL) = D X Unit Weight of Concrete = 0.125 X 25 = 3.125 kN/m2b) Live Load (LL) = 2 kN/m2 …[Refer Table No. 1 , Page No. 7 , I.S. 875 (Part 2) : 1987]c) Super Imposed Dead Load (SIDL) =Floor Finish = Wt. of Screeding (50 mm Thk.) + Flooring (10 mm Thk.) = (0.05 X 24) + (0.01 X 22) …[Refer I.S. 875 (Part 1) : 1987] = 1.42kN/m2 ≈ 1.5 kN/m2Total Load of Slab S1 (w) = 3.125 + 2 + 1.5 = 6.625 kN/m2 Triangular Load of Slab S1 is Transferring on Beam B6 Because S1 Slab is Two Way Slab Which is Given by,WS1 = [(w. Lx)/3] = [(6.625 X 2.66)/3) = 5.874 kN/mTherefore, Total Load of Slabs Transfering on Beam B6 = WS1 + WS2 = 5.874+7.678 = 13.55 kN/m iii) Self Weight of Beam (DL) = b X D X Unit Weight of Concrete = 0.230 X 0.375 X 25 = 2.156 kN/mTotal Load on Beam B6 = Wall Load + Slab load + Self Wt. of Beam = 9 + 13.55 + 2.156 = 24.706 kN/mUltimate Load (Wu) = 24.706 X 1.5 = 37.059 kN/m. Step 4 :- Bending Moment (Mu) :- Mu= Wu . Le2/ 8 = 37.059 X 3.0042 / 8 = 41.8 kN.m Step 5 :- Check For Depth :- Equate Mumax & Mulim, Mumax = Mulim41.8 X 106 = 0.133 X fck X b X dreq2 41.8 X 106 = 0.133 X 20 X 230 X dreq2dreq= 261.38 mm < 344mm …(dreq< dprovided) Therefore, Safe Step 6 :- Area of Steel Calculations (Ast) :- [Refer Cl. No. 26.5.1.1 (a) & (b),Page No. 46 & 47,I.S. 456 : 2000] Therefore, Provide 4-T12 Bars.Therefore, Astprovided = (One Bar Area). (No. of Bars to be Provided) = π/4 X〖 12〗^2 X 4 Astprovided = 452.45 mm2 >Astmin (134.504 mm2) …ok >Astmax (3450 mm2) …ok Step 7 :- Check For Shear :- Codal Provisions for Shear :- [Refer Cl. No. 26.5.1.6, Page No. 48 & Cl. No. 40.1, 40.3, Page No. 72 of I.S. 456 : 2000] i) Maximum Shear Force (Vu) :-Vu= Wu . Le/ 2 ….( For Simply Supported Beam ) = [(37.059 X 3.004) / 2] = 55.662 kN ii) Nominal Shear Stress (τv) :-τv = Vu / b.d = [(55.662 X 103) / (230 X 344)]= 0.7 N/mm2 iii) % of Steel (Pt) :-Pt= [(100. Astprovided) / b.d]Therefore , Pt = (100 X 452.45) / (230 X 344) = 0.57 % iv) Design Shear Stress (τc) :- (Refer Table No. 19, Page No.73, I.S. 456 : 2000)By Interpolation,τc = [0.48 + {(0.56-0.48) / (0.75-0.5)}X (0.57-0.5)] = 0.5 N/mm2 < 0.7 N/mm2As, τc < τvWe Need to Design For Shear Reinforcement. Pt τc (For M20) 0.5 0.48 0.57 ? 0.75 0.56 As per Table No. 20 , Page No. 73 , I.S. 456 : 2000Maximum Shear Stress for M20 Grade Concrete is, τcmax= 2.8 N/mm2Therefore, Beam B6 is Safe in Shear. Step 8 :- Design of Shear Reinforcement :- i) Shear Resisted by Stirrups (Vus) :-Vus= Vu – Vuc ….( For Simply Supported Beam ) = Vu – τc .b.d = 55.662 X 103 – 0.5 X 230 X 344 = 16102 N = 16.102 kNProvide 2-Legged 8mm Diameter StirrupsAsv = 2 X π/4 X 64 = 100.544 mm2 ii) Spacing of Stirrups (Sv) :- iii) Check For Stirrups Spacing :-Spacing of Stirrups Should Not be Greater Than Minimum of The Following,Spacing of Stirrups (Sv) = Min. of i) 0.75d ii) 300 mmTherefore,

MANUAL DESIGN OF SINGLY REINFORCED BEAM Read More »