Manual Design Of Footing Of G+5 Building Using I.S. 456:2000

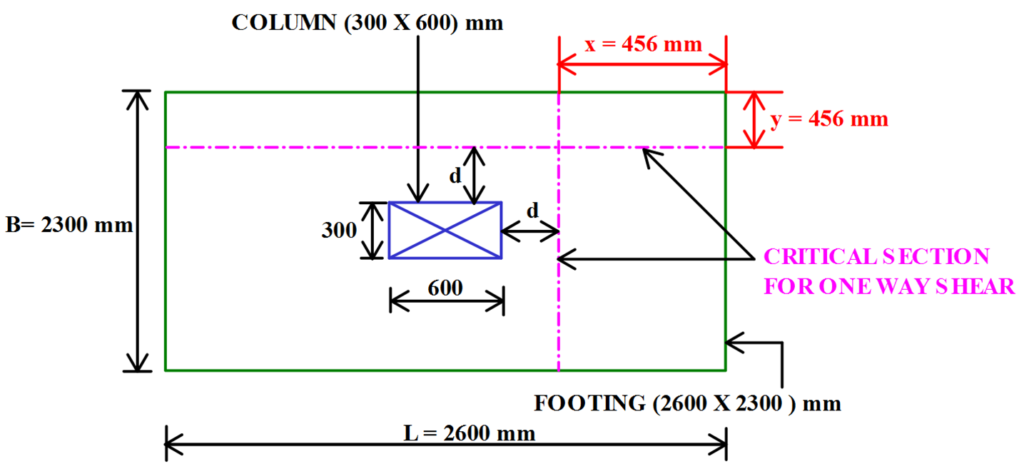

In this blog you will learn Manual Design Of Footing of G+5 Building Using I.S. 456:2000 with the help of example. Step by step guid to clear conceptLearn Complete Structural Engineering Indusry Requirements Practically With Our Daily Blogs Series Given: Load Calculation (Step 1): Load From Column = 1500 kN Self Weight of Footing = Assume 10% of the column load = (10/100) X 1500 = 150 kN ———————————————————–Total Weight (W) = 1650 kN Area of Footing (A) (Step 2): Area of Footing (A) = Total Weight (W) / Net Soil Bearing Capcity (S.B.C.)= 1650 / 300= 5.5 m2Take Equal Projections From Both Sides, 5.5 = (0.6 + 2x) . (0.3 + 2x)5.5 = 0.18 +1.2x + 0.6x + 4×25.5 = 0.18 +1.8x + 4×2Therefore, by Solving Above Equation,x = 0.95 mTake Projection of 1 m on Both Side. Therfore, Size of Footing = (0.3+ 2 X 1 ) & (0.6 + 2 X 1) = 2.3 X 2.6 mTherefore Area of Footing Provided = 2.3 X 2.6 = 5.98 m2 Upward Soil Pressure (Pau) (Step 3): Pau = (Factored Load of Column / Actual Area of Footing Provided) = 1.5 X 1500 / 5.98Pau= 376.25 kN/m2 Bending Moment (B.M.) (Step 4): The Critical Section for B.M. Along the Column Face as Shown in the Figure 2, From X-axis: = (2.6 – 0.6) / 2 = 1 mConsider a Strip of 1m.Therefore, Mux = [Pau X 1 X (Cx2/2)] = [376.25 X 1 X (12 /2)] Mux = 188.125 kN.m From Y-axis: = (2.3 – 0.3) / 2 = 1 mTherefore, Muy = [Pau X 1 X (Cy2/2)] = [376.25 X 1 X (12 /2)] Muy = 188.125 kN.m Depth of Footing Required (dreq) (Step 5): Equate The Maximum Bending Moment (Max. of Mux & Muy) With Limiting Moment of Resistance ,Consider a Strip of 1m.Mumax= Mulim188.125 X 106 = 0.133 fck.b.dreq2188.125 X 106 = 0.133 X 20 X 1000 X dreq2dreq = 265.94 mmProvide 12 mm Diameter Bars at a Clear Cover of 50 mm.Therefore, Overall Depth (D) = 265.94 + 50 + (12/2) = 321.94 mm ≈ 600 mm …(rounded -off on higher side) Overall Depth (D) = 450 mmTherefore, Effective Depth Provided (dprovided) = 600 – 50 – (12/2) = 544 mm Area of Steel Calculation (Ast) (Step 6): Astx Along X-Direction: Astx = 826.8 mm2Provide 12 mm Diameter Bars.Spacing = (π/4 × 12² ÷ 826.8) ×100 = 136.8 mm ≈ 125 mmProvide 12 mm Diameter Bars @ 125 mm c/c Asty Along Y-Direction: Asty = 826.8 mm2Provide 12 mm Diameter Bars.Spacing = (π/4 × 12² ÷ 826.8) ×100 = 136.8 mm ≈ 100 mmProvide 12 mm Diameter Bars @ 100 mm c/c Check For One Way Shear (Step 7): The Critical Section for One Way Shear is Taken at a Distance of ‘d’ From Column Periphery. The Offset x = Cx – d = 1 – 0.544 = 0.456 mSimilarly, y = Cy – d = 1 – 0.544 = 0.456 mDepth of Footing at Critical Section (d’) = 544 mm Shear Force Along X-Direction :-Vux = x . L . Pau = 0.456 X 1 X 376.25 = 171.57 kN Shear Force Along Y-Direction :-Vuy = y . B . Pau = 0.456 X 1 X 376.25 = 171.57 kN Vumax = 209.2 kN Nominal Shear Stress (τv): τv = Vumax/ b’.d’ = [(171.57 X 103) / (1000 X 544)] = 0.32 N/mm2 % of Steel (Pt): Pt = 100 Astmax / b’d’ = [(100 X 1130) / (1000 X 544)] = 0.21 % Design Shear Stress (τc): τc = 0.32 N/mm2 > 0.32 N/mm2As, τc > τv … Safe in One Way Shear Pt τc ( For M20) <0.15 0.28 0.21 ? 0.25 0.36 Refer Table No. 19, Page No.73, I.S. 456 : 2000 Check For Two Way Shear (Step 8): The Critical Section for Two Way Shear is Taken at a Distance of ‘d/2’ From Column Periphery. Depth of Footing at Critical Section (D’) = 750 mmEffective Depth at Critical Section = d’ = 600 – 50 – (12/2 ) = 544 mmb’ = 2 . Perimeter of Critical Section = 2 X (1144 + 844) = 3976 mm Shear Force on Shaded Area is Given by,Vu = (Footing Area – Critical Section Area) . Upward Soil PressureVu = [(2.6 X 2.3) – (1.144 X 0.844)] X 376.25Vu = 1886.7 kN Nominal Shear Stress (τv): τv = Vumax/ b’. d’ = [(1886.7 X 103) / (3976 X 544)] = 0.87 N/mm2 Design Shear Stress (τc’): τc‘= ks. (0.25√fck )Where, ks= Minimum of, i) 1 ii) 0.5 + βc = 0.5 + 0.5 = 1 Where, βc = (Breadth / Depth)column = 300 / 600 = 0.5Therefore, ks= 1 Therefore, τc‘= 1 X (0.25√20) = 1.118 N/mm2 > 0.87 N/mm2As, τc > τv … Safe in Two Way Shear

Manual Design Of Footing Of G+5 Building Using I.S. 456:2000 Read More »