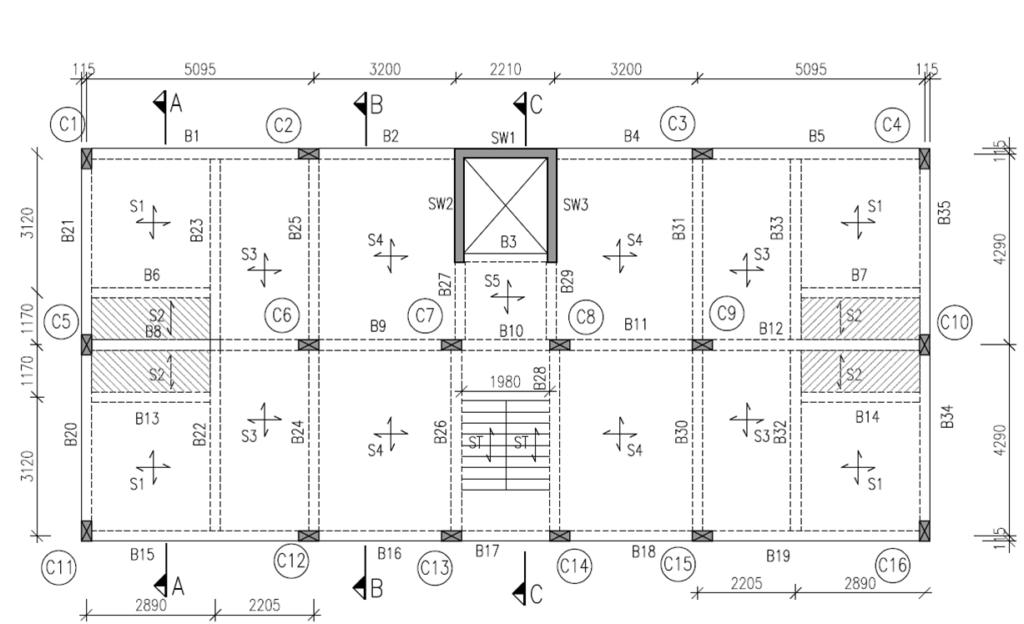

In this blog you will learn about Design of one way slab of first floor of G + 5 building procedure using I.S. 456:2000. Learn Complete Structural Engineering Industry Requirements Practically With Our Daily Blogs Series

Steps:-

Given:-

1) Grade of Concrete = M20

2) Grade of Steel = Fe500

3) Clear Cover to Reinforcement (c) = 20 mm

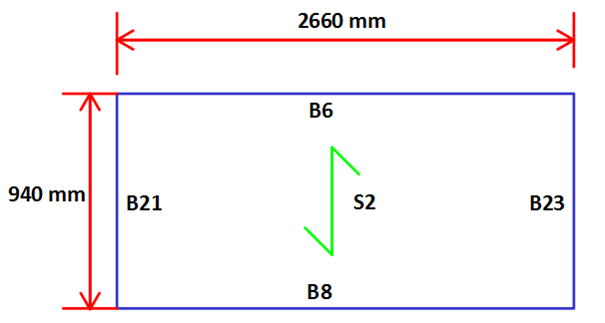

4) Dimension of Slab = (940mm X 2660 mm)

5) Assume Beam Support (Bearing) = 230 mm

6) Unit Weight of Concrete = 25 kN/m2

Step 1 :-Aspect Ratio

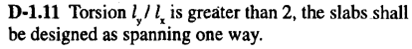

(Refer Cl. No. D-1.11, Page No. 90 , I.S. 456:2000)

Lx = 940 mm & Ly = 2660 mm …(Given)

Therefore, Ly/Lx = 2660/940 = 2.82 > 2 …(One Way Slab)

Step 2 :-Trial Depth of Slab (D)

Basic Value (B.V.) = L / D = 20

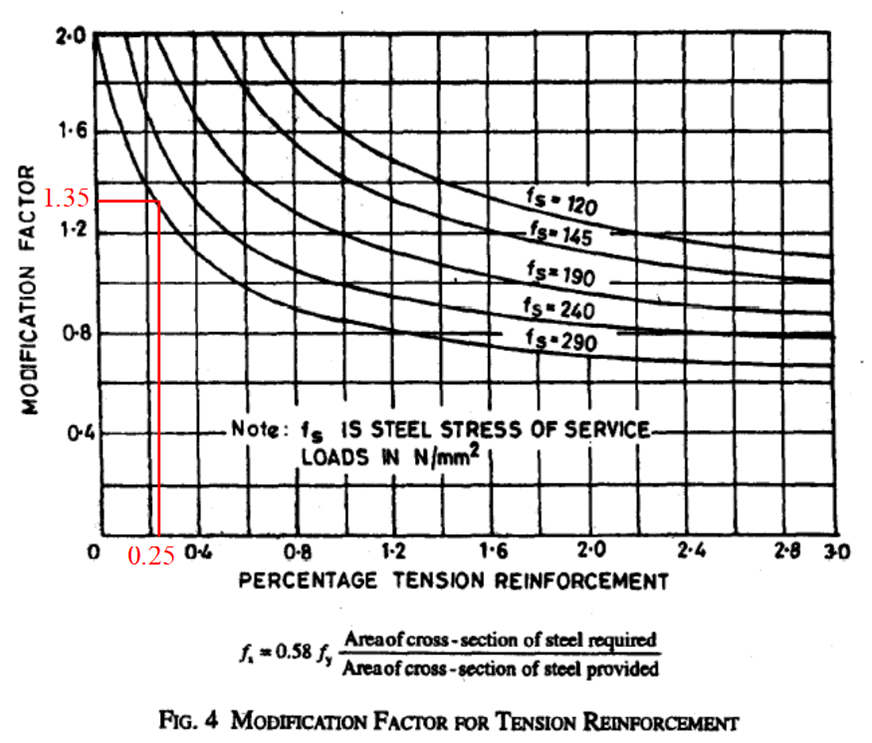

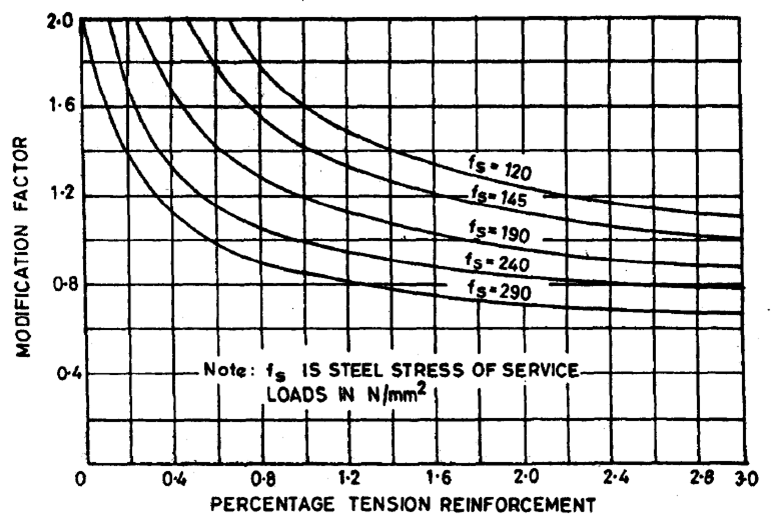

Assume % of Steel = 0.25 %

Therefore, Modification Factor (M.F.) = 1.35 …(Refer Fig. 4 , Page No. 38 I.S.456:2000)

Therefore, Effective Depth (d) = SPAN/B.V.X.N.F. = [940/ (20 X 1.35)] = 34.81 mm

Assume Bars to be Provided of Diameter = 8 mm & Provide Clear Cover to Reinforcement = 20 mm

Therefore, Overall Depth of Slab (D) = d + c + (8/2) = 34.81 + 20 + 4 = 58.81 mm

Assume , Overall Depth of Slab (D) = 125 mm

Therefore, Effective Depth Provided (dprovided) = D – c – (8/2) = 125 – 20 – 4 = 101 mm

Step 3 :-Effective Span (le)

Minimum of, i) Le = Lx + Bearing = 940 + 230 = 1170 mm

ii) Le = Lx + d = 940 + 101 = 1041 mm

Therefore, Effective Span (Le) = 1041 mm

Step 4 :- Load Calculations

Consider 1 m Strip of Slab,

i) Self Weight of Slab (DL) = D X Unit Weight of Concrete

= 0.125 X 25

= 3.125 kN/m2

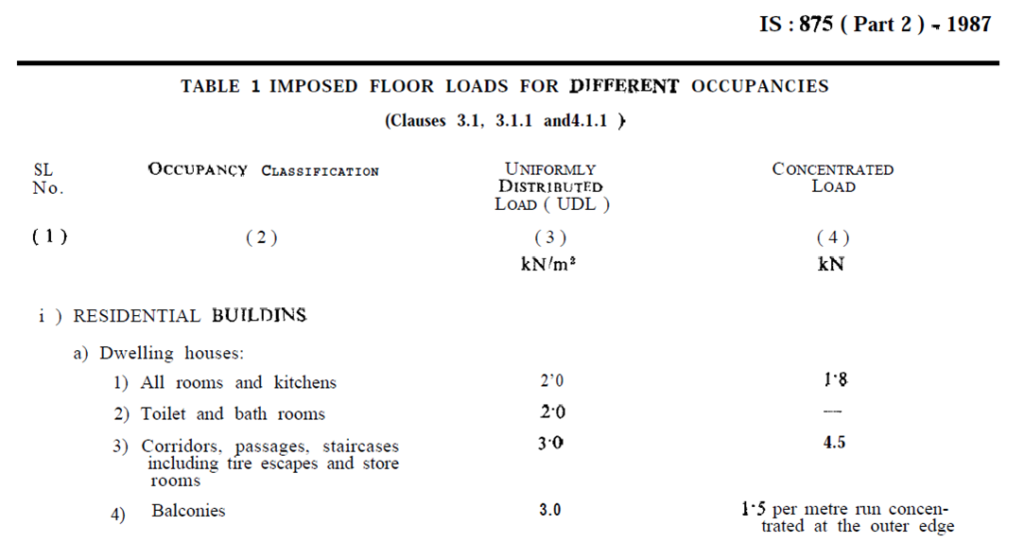

ii) Live Load (LL) = 2 kN/m2 …[Refer Table No. 1 , Page No. 7, I.S. 875 (Part 2) : 1987]

iii) Super Imposed Dead Load (SIDL) =

Floor Finish = Wt. of Screeding (50 mm Thk.) + Flooring (10 mm Thk.) + Sunk Load(325 mm Thk.)

= (0.05 X 24) + (0.01 X 22) + (0.325 X 20)…[Refer I.S. 875 (Part 1) :1987]

= 7.92 kN/m2

≈ 8 kN/m2

Total Load (W) = 3.125 + 2 + 8

= 13.125 kN/m2

Total Ultimate Load (Wu) = 13.125X 1.5 ≈ 19.7 kN/m2

Step 5 :- Maximum Design Bending Moment (Mumax)

Refer Table No. 26, Page No. 90 , I.S. 456:2000

Span Moment :-

Mumax= Wu . le2 / 8

Mumax = 19.7 X 1.0412 / 8

Mumax = 2.668 kN.m

Therefore ,Mumax= 2.668 kN.m

Step 6 :- Check For Depth

Equate Mumax & Mulim,

Mumax = Mulim

2.668 X 106 = 0.133 X fck X b X dreq2

2.668 X 106 = 0.133 X 20 X 1000 X dreq2

dreq= 31.67 mm < 101mm …(dreq< dprovided)

Therefore, Safe

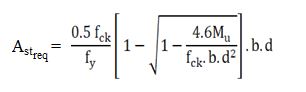

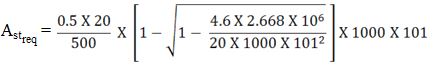

Step 7 :- Area of Steel Calculation :-

Spacing of Bars :-

As per Cl. No. 26.3.3 (b) , Page No. 46 , I.S. 456 : 2000

Maximum Spacing

Between Bars < Minimum of i) 3d

ii) 300 mm

Therefore,

Maximum Spacing Between Bars = i) 3 X 101 = 303 mm

ii) 300 mm

Note:- Generally We Provide 200 mm Maximum Spacing Between Bars.

= 61.7 mm2

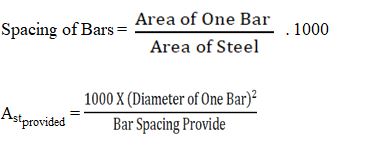

Spacing of Bars = (Area of One Bar / Area of Steel) . 1000

Consider Bars to Provide are of Diameter 8mm.

Therefore, Spacing of Bars = [(π/4) X 82 / 61.7] X 1000 = 814.78 mm

Note:- Generally We Provide 200 mm Maximum Spacing Between Bars.

Therefore, Provide 8 mm Diameter Bars at 200 mm c/c.

Step 8 :- Distribution Steel Calculation :-

Dst = 0.12 % of the Gross Area of Slab …(For Fe500)

Therefore, Dst= (0.12/100) X Ag

Dst= (0.12/100) . b . D …(Where, b = 1000 mm &

D = Overall Depth of Slab)

Dst= (0.12/100) X 1000 X 125

= 150 mm2

Spacing of Bars = (Area of One Bar / Area of Steel) . 1000

Consider Bars to be Provide are of Diameter 8 mm.

Therefore, Spacing of Bars = [(π/4) X 82 / 150] X 1000 = 335.15 mm

Maximum Spacing

Between Bars < Minimum of i) 5d = 5 X 101 = 505 mm

ii) 450 mm

Note:- Generally We Provide 200 mm Maximum Spacing Between Bars.

Therefore, Provide 8 mm Diameter Bars at 200 mm c/c.

Step 9 :- Check For Deflection :-

% of Steel = Pt = 100. Astreq / b.d

Therefore, Pt = (100 X 61.7) / (1000 X 101) = 0.061 %

Therefore, Fs = 0.58 X 500 X (61.7 / 251.36) = 71.18 N/mm2

% of Steel Provided = Pt = 100. Astprovided / b.d

Therefore , Pt = (100 X 251.36) / (1000 X 101) = 0.248 %

M.F. = 2.0

As, dreq < dprovided …Safe for Deflection.

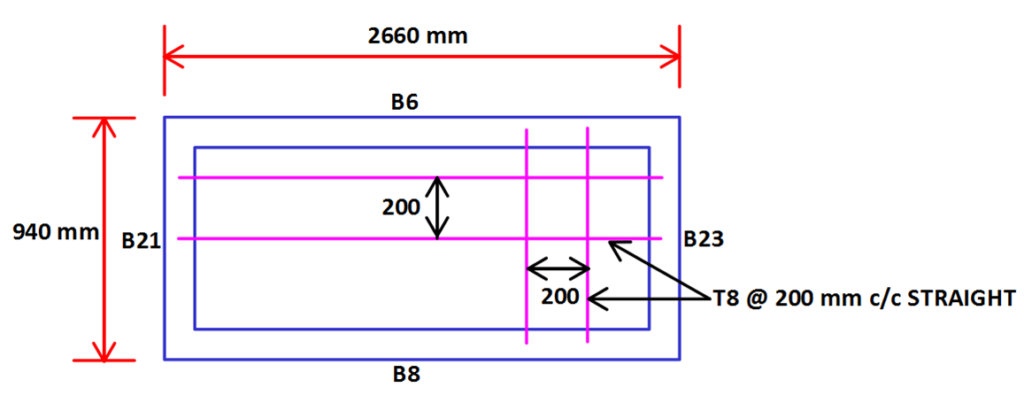

REINFORCEMENT DETAILS :-

Nice effort!!

Well described

Nice Blog