In this blog, you will learn step by step about the design of doubly reinforced beam of first floor of G+5 building procedure using I.S. 456:2000. For daily blogs, subscribe to our blog page and learn complete information about the structural engineering industry

Steps:-

Given:-

1) Grade of Concrete = M20

2) Grade of Steel = Fe500

3) Clear Cover to Reinforcement (c) = 25 mm

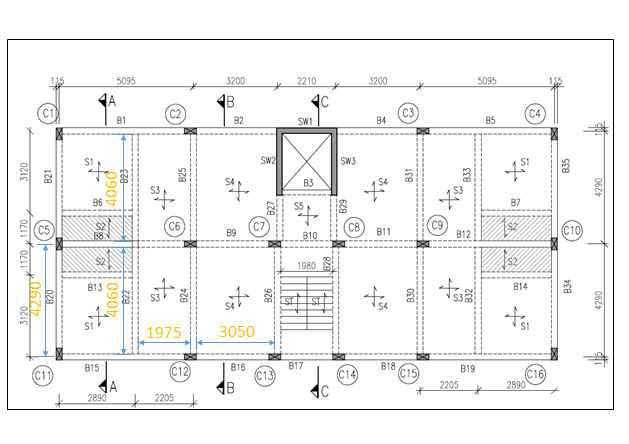

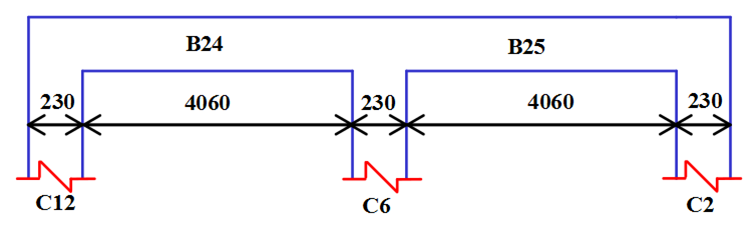

4) Length of Beam :- B24 & B25 = 4060 mm

5) Unit Weight of Concrete = 25 kN/m2

6) Slab Dimensions :- S3 = (1975 mm X 4060 mm) & S4 = (3050 mm X 4060 mm)

7) Floor to Floor Height (H) = 3000 mm

Step 1 :- Trial Dimension of The Beam :-

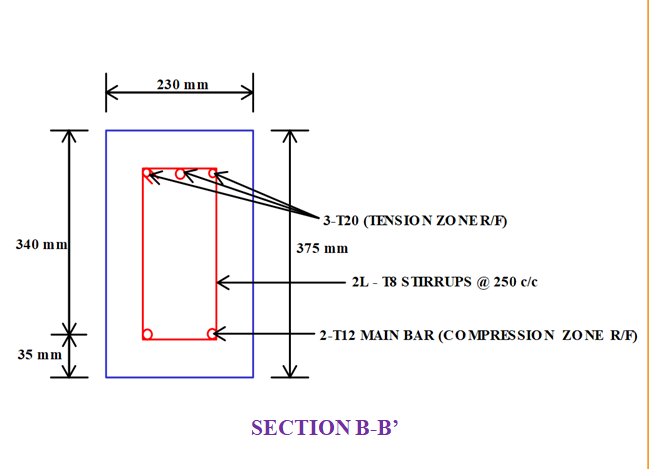

Assume the Width of The Beam (b) = 230 mm

Effective Depth of Beam (d) = (L/10) to (L/15) = (4290/10) to (4290/15)

= 429 mm to 286 mm

Take, d = 325 mm

Assume, 20 mm Diameter Bars are to be Provided at a Clear Cover of 25 mm.

Therefore, Overall Depth (D) = 325 + (20/2) + 25 = 360 mm ≈ 375 mm

…(Rounded off on Higher Side)

Therefore, Effective Depth of Beam Provided (d) = 375 – (20/2) – 25 = 340 mm

Step 2 :- Effective Span (Le) :-

Minimum of The Following ,

i) Le = L + d = 4060 + 340 = 4400 mm

ii) Le = L + Bearing = 4060 + 230 = 4290 mm

Therefore, Effective Span (Le) = 4290 mm

Step 3 :- Load Calculations :-

Load on Beam B24 & B25 :-

i) Super Imposed Dead Load (SIDL) :-

Wall Load = Wall Thickness X Floor to Floor Height X Unit Weight of Bricks

= (0.150 X 3 X 20) = 9 kN/m

…(No Deduction of Depth of Beam is Made From Floor to Floor Height)

ii) Slab Load Transferring on Beam :-

Slab S3 :-

a) Self Weight of Slab (DL) = D X Unit Weight of Concrete

= 0.125 X 25

= 3.125 kN/m2

b) Live Load (LL) = 2 kN/m2 …[Refer Table No. 1 , Page No. 7 , I.S. 875 (Part 2) : 1987]

c) Super Imposed Dead Load (SIDL) =

Floor Finish = Wt. of Screeding (50 mm Thk.) + Flooring (10 mm Thk.)

= (0.05 X 24) + (0.01 X 22) …[Refer I.S. 875 (Part 1) : 1987]

= 1.42 kN/m2

≈ 1.5 kN/m2

Total Load of Slab S3 (w) = 3.125 + 2 + 1.5 = 6.625 kN/m2

Trapezoidal Load of Slab S3 is Transferring on Beam B24 & B25 Because S3 Slab is Two Way Slab Which is Given by,

WS3 = [{(w. Lx)/2} X {1- (1/ 3. β2)}] Where, β = l_y/l_x

= {(6.625 X 1.975 ) / 2} X [1- {1/ 3 X (4.06/1.975)2}]

= 6.02 kN/m

Slab S4 :-

a) Self Weight of Slab (DL) = D X Unit Weight of Concrete

= 0.125 X 25

= 3.125 kN/m2

b) Live Load (LL) = 2 kN/m2 …[Refer Table No. 1, Page No. 7, I.S. 875 (Part 2) : 1987]

c) Super Imposed Dead Load (SIDL) =

Floor Finish = Wt. of Screeding (50 mm Thk.) + Flooring (10 mm Thk.)

= (0.05 X 24) + (0.01 X 22) … (Refer I.S. 875 (Part 1) : 1987)

= 1.42kN/m2

≈ 1.5 kN/m2

Total Load of Slab S4 (w) = 3.125 + 2 + 1.5 = 6.625 kN/m2

Trapezoidal Load of Slab S4 is Transferring on Beam B24 & B25 Which is Given by,

WS4 = [{(w. Lx)/2} X {1- (1/ 3. β2)}]

={(6.625 X 3.05) / 2} X [1- {1/ 3 X (4.06/3.05)2}]

= 8.2 kN/m

Therefore, Total Load of Slabs Transfers on Beam B24 & B25 = WS1 + WS4

= 6.02 + 8.2

= 14.22 kN/m

iii) Self Weight of Beam (DL) = b X D X Unit Weight of Concrete

= 0.230 X 0.375 X 25

= 2.156 kN/m

Total Load on Each Beam B24 & B25 (W) = 9 + 14.22 + 2.156 = 25.376 kN/m

≈ 25.4 kN/m

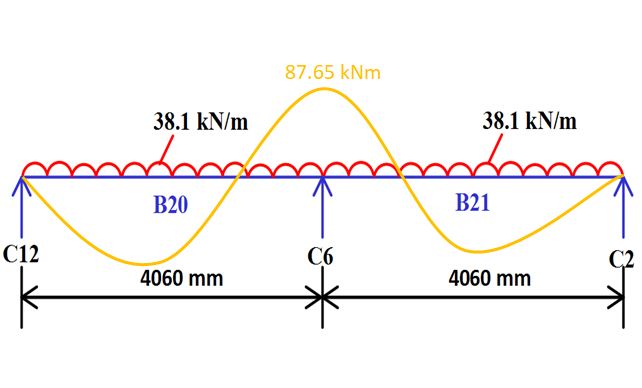

Ultimate Load (Wu) = 25.4 X 1.5 = 38.1 kN/m

Step 4 :- Bending Moment (Mu) :-

Max. Moment on Continuous

Beam (B24 & B25) is (M) = W . Le2 / 8

= (25.4 X 4.292) / 8

= 58.43 kN.m

Ultimate Moment on Continuous

Beam (B20 & B21) is (Mu) =58.43X 1.5 = 87.65 kN.m

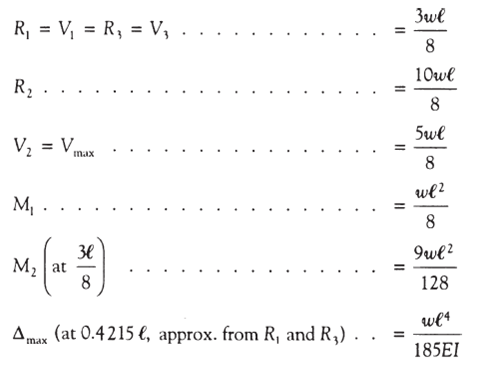

CONTINUOUS BEAM HAVING TWO EQUAL SPAN CARRYING UNIFORMALLY DISTRIBUTED LOAD (UDL) OVER ENTIRE SPAN :-

Step 5 :- Limiting Moment of Resistance :-

Mulim= 0.133 fck.b.d2

Mulim= 0.133 X 20 X 230 X 3402

Mulim= 0.133 X 20 X 230 X 3402

Mulim= 70724080 N

Mulim= 70724080 / 106

Mulim= 70.72 kN.m

As, Mulim< Mu

Note :- Either We Have to Increase Depth and Design as a Singly Reinforced Beam or if We Are Not Allowed to Increase Depth of Beam Then We Will Design the Beam as a Doubly Reinforced Beam. So We Design Assumed Beam of 230 X 375 mm As Doubly Reinforced Beam.

Step 6 :- Balanced Moment (Mu2) :-

Equate, Mu2 = Mu – Mulim

Mu2 = 87.65 – 70.72

Mu2 = 16.93 kN.m

Step 7 :- Area of Steel Calculation (Ast) :-

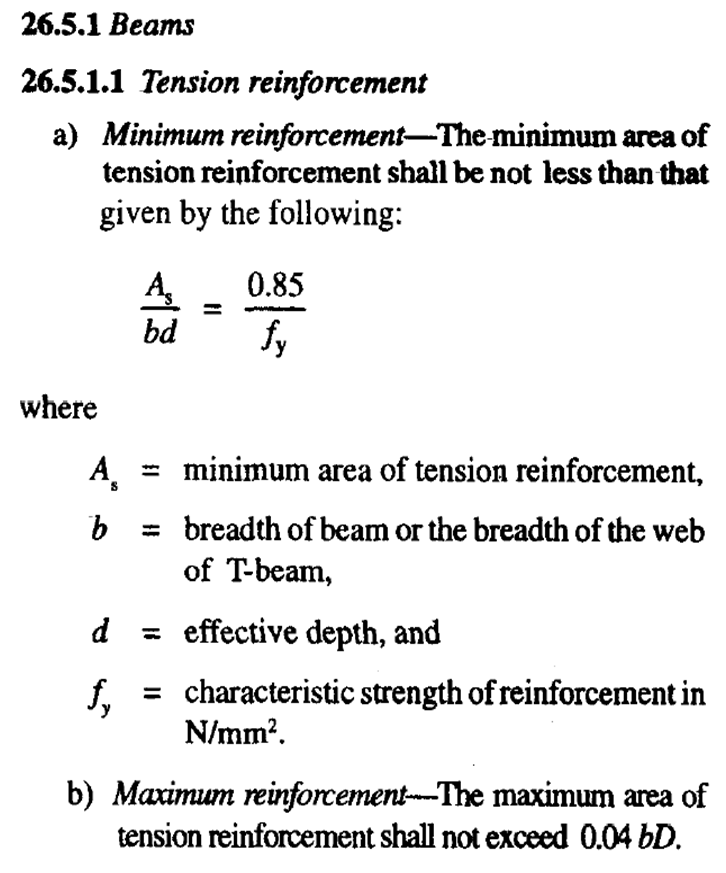

[Refer Cl. No. 26.5.1.1 (a) & (b), Page No. 46 & 47,I.S. 456 : 2000]

Astmin = As/bd = 0.85/ Fy

Astmin= As = [(0.85 X 230 X 340) / 500]

Astmin= As = 132.94 mm2

Astmax = 0.04 b.D

= 0.04 X 230 X375

= 3450 mm2

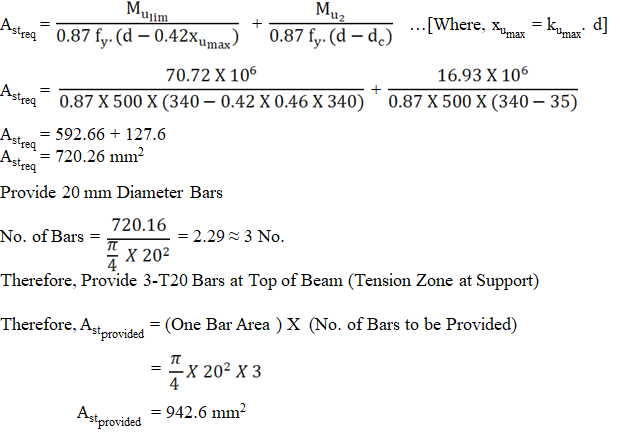

i) Steel in Tensile Zone :-

Astreq= Ast1+Ast2

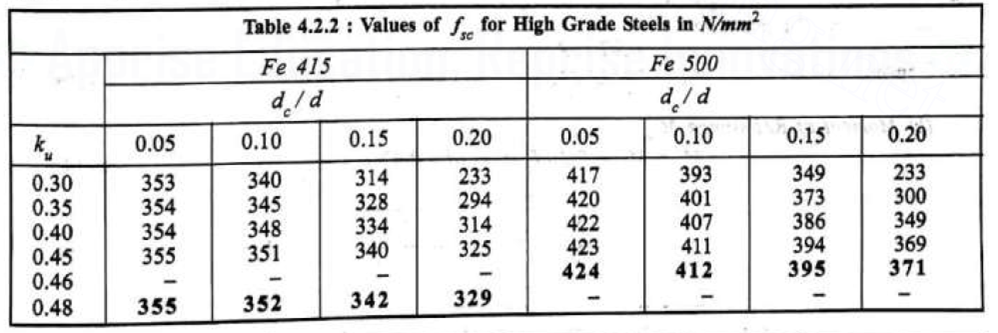

[For kumax & fsc Refer above Tables From, Illustrated Design of Reinforced Concrete Buildings by S. R. Karve & V. L. Shah]

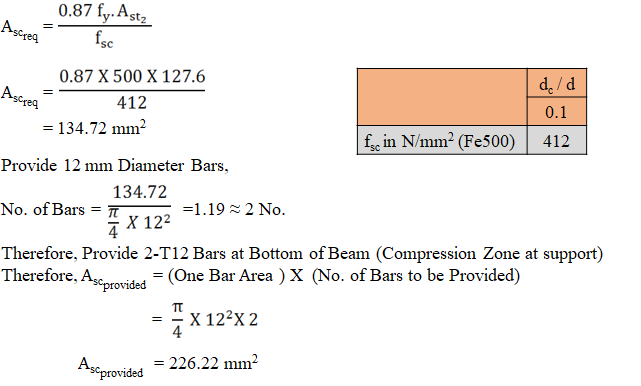

ii) Steel in Compression Zone :-

dc / d= (D – d) / d = (375 – 340) / 340 = 0.1

By Interpolation,

fsc = 412 N/mm2 …Refer Table 4.2.2

Step 8 :- Check For Shear :-

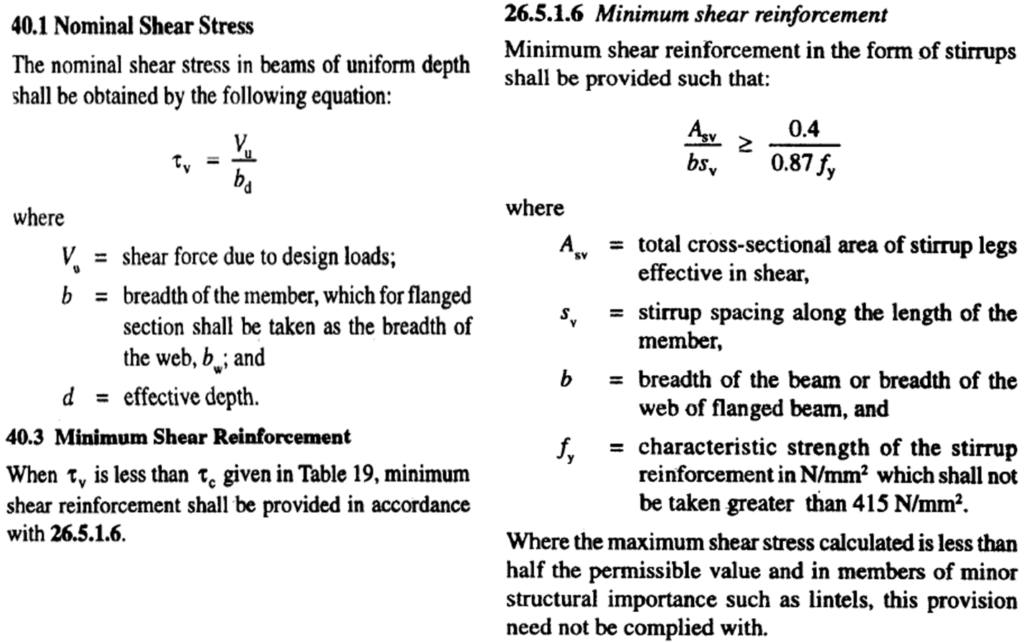

Codal Provisions for Shear :- [Refer Cl. No. 26.5.1.6, Page No. 48 & Cl. No. 40.1, 40.3, Page No. 72 of I.S. 456 : 2000]

i) Maximum Shear Force (Vu) :-

V = (5.W . Le/ 8)

= [(5 X 25.4 X 4.29) / 8]

= 68.1 kN

Vu= 68.1 X 1.5 = 102.15 kN

ii) Nominal Shear Stress (τv) :-

τv = Vu / b.d

= [(102.15 X 103) / (230 X 340)]

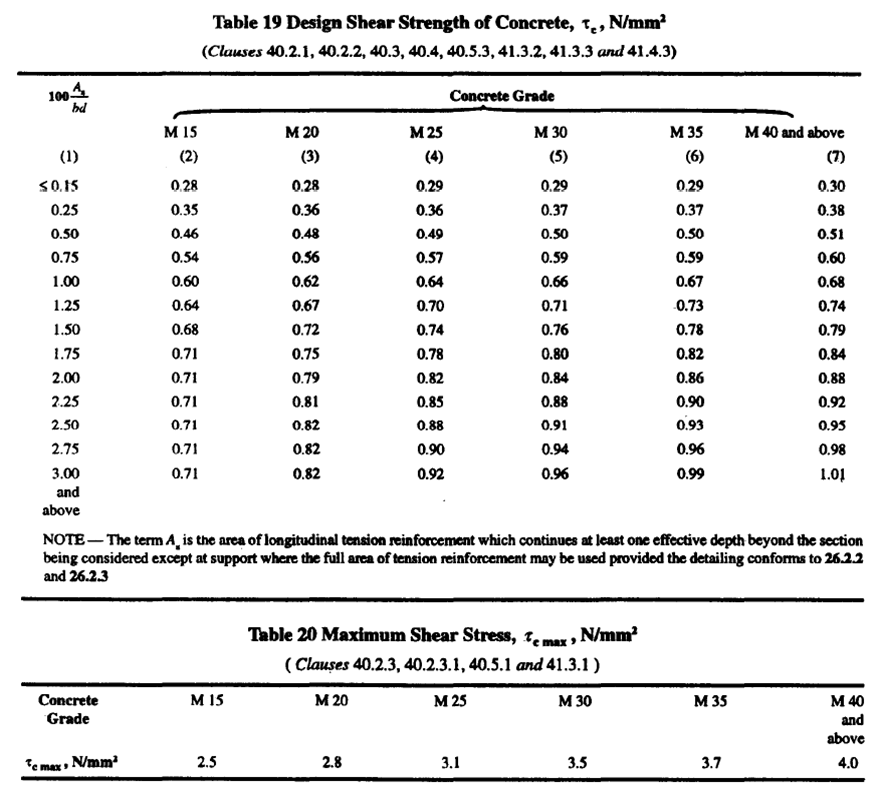

= 1.3 N/mm2 < 2.8 N/mm2 (τcmax) (Refer Table 20, I.S. 456:2000)

iii) % of Steel (Pt) :-

Pt= [(100. Astprovided) / b.d]

Therefore , Pt = (100 X 942.6) / (230 X 340) = 1.2 %

iv) Design Shear Stress (τc) :- (Refer Table No. 19, Page No.73, I.S. 456 : 2000)

By Interpolation,

τc = [0.62 + {(0.67- 0.62) / (1.25 – 1)}X (1.2 – 1)]

= 0.66 N/mm2 < 1.29 N/mm2

As, τc < τv

We Need to Design For Shear Reinforcement.

As per Table No. 20 , Page No. 73 , I.S. 456 : 2000

Maximum Shear Stress for M20 Grade Concrete is, τcmax= 2.8 N/mm2

Therefore, Beam B20 & B21 Both Are Safe in Shear.

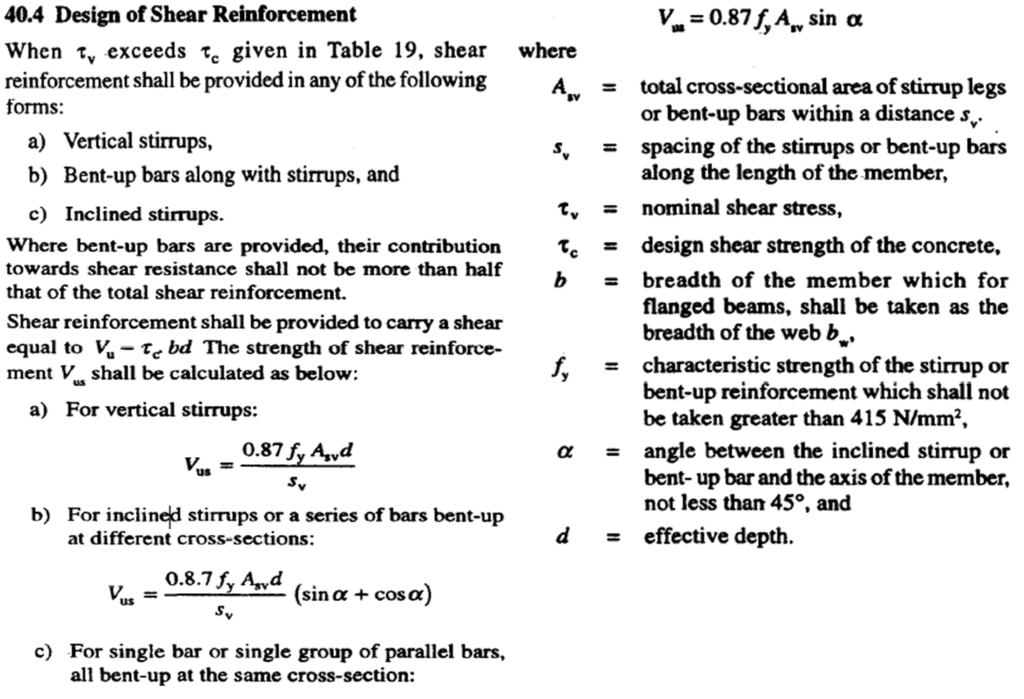

Step 9 :- Design of Shear Reinforcement :-

(Refer Cl. No. 40.1, Page No. 73 of I.S. 456 : 2000]

i) Shear Resisted by Stirrups (Vus) :-

Vus= Vu – Vuc ….( For Simply Supported Beam )

= Vu – τc .b.d

= 102.15 X 103 – 0.66 X 230 X 340

= 50538 N

= 50.538 kN

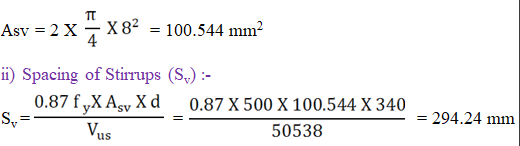

Provide 2-Legged 8mm Diameter Stirrups

iii) Check For Stirrups Spacing :-

Spacing of Stirrups Should Not be Greater Than Minimum of The Following,

Spacing of Stirrups (Sv) = Min. of i) 0.75d

ii) 300 mm

Therefore, Spacing of Stirrups (Sv) = i) 0.75 X 390 = 292.5 mm < 294.24 mm Or

ii) 300 mm > 294.24 mm

Therefore, Spacing of Stirrups (Sv) = 292.5 mm ≈ 250 mm

Therefore, Provide 2-Legged 8 mm Diameter Stirrups at a Spacing of 250 mm c/c.

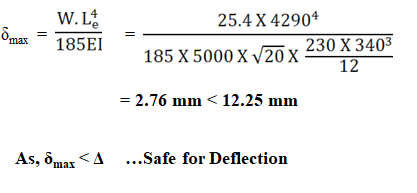

Step 10 :- Check For Deflection :-

Permissible Deflection (Δ) = Le / 350 = 4290 / 350 = 12.25 mm

For Simply Supported Beam,

Civil engineering

The formula is so helpful